Machining processes

Standard and custom

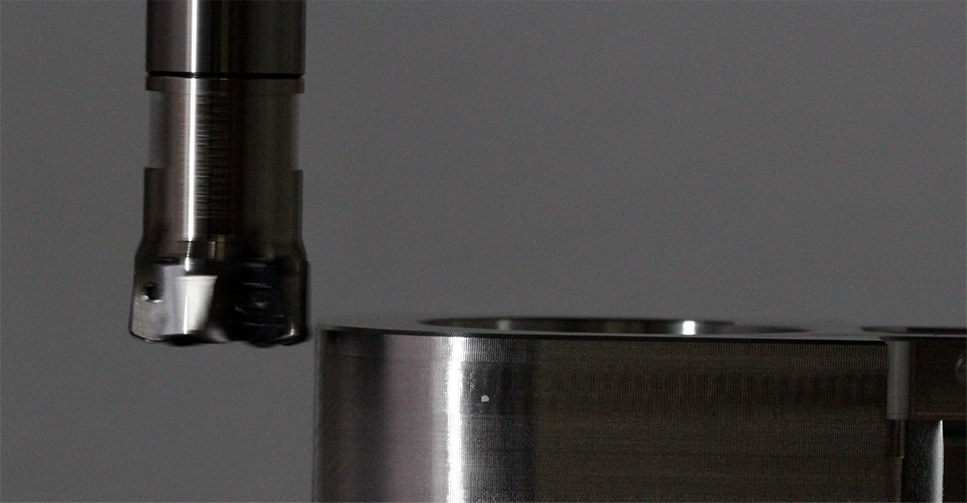

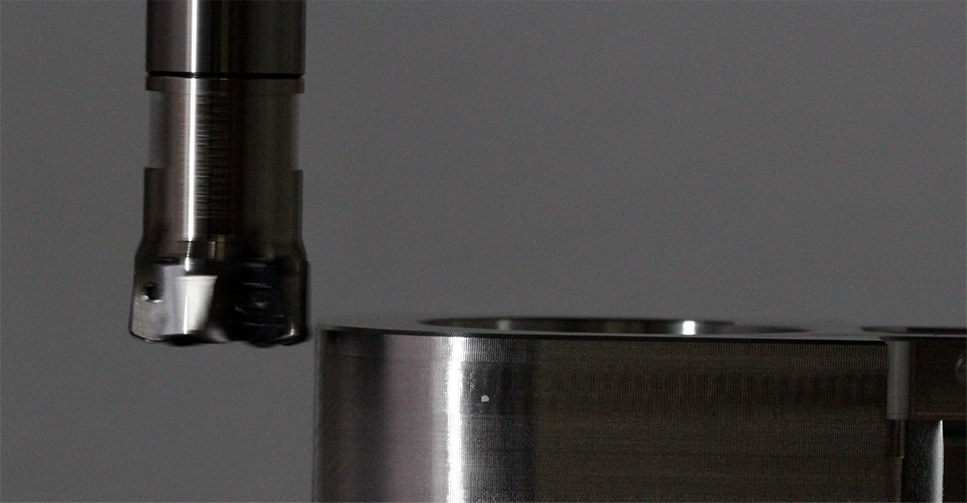

milling

End milling, chamfering, surface flattening are the operations carried out by OZ for standard projects as well as custom projects using Yamazaki Mazak CNC machining centres at every level: from degreasing to super-finishing. Not only precision machining, but also grinding: we export the material reduced to minute chips in order to preserve the cutting of the grinding tool. Before the start and after the end of each work phase, the specialist technician checks that the machine is properly lubricated and that every part is protected against abrasive dust.

Yamazaki Mazak VCN 510C II

1020 x 500 x 510

Yamazaki Mazak VCN 510 C

1020 x 500 x 510

Yamazaki Mazak VTC 300 C

1660 x 600 x 650

Centro Yamazaki Mazak VTC 530 C

1660 x 530 x 610

Yamazaki Mazak VTC 760 C

1740 x 600 x 650

Yamazaki Mazak FJV 250

1020 x 500 x 510

Yamazaki Mazak VRX600i

Axes 5, ø 630

Yamazaki Mazak CV5-500

Axes 5, ø 500

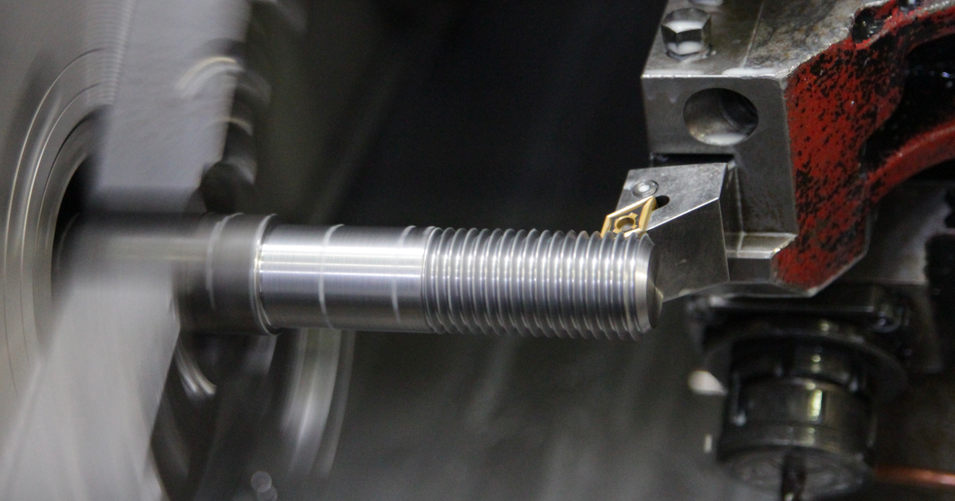

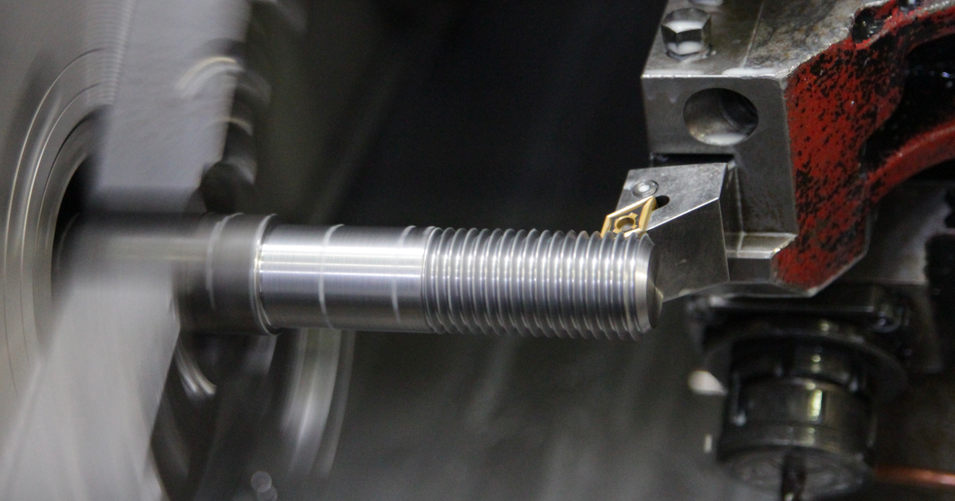

TURNING

Non-standard?

No problem!

Our company carries out the turning operation using advanced machining centres and under the strict supervision of the project team. The Yamazaki Mazak CNC Machining Centre allows us to reduce the bar feed to 42 mm and the width to 400 mm, so that we can work on even smaller pieces and manage all nonstandard projects without any problems.

Yamazaki Mazak QNT200M

ø250 x x1000

Yamazaki Mazak QTN200M

ø250 x 500

Yamazaki Mazak Integrex IV 200ST

ø250 x 1000

other services

Mechanical workshop and more

Assemblies

What is the best way to check the performance of the semi-finished product, if not the assembly? The work team assembles small mechanical units inside the company, so as to check the functionality of each single piece that leaves the mechanical workshop and to test the component.

Surface finishes

Anodic oxidation, phosphating, hardening, burnishing, cementation, galvanising, nitriding, nickel plating: the surface finishes are carried out externally.

CAD-CAM

We provide support for CAD-CAM machining, with two Future-CAM stations.

Consultation

Precision and optimisation are our strengths: that’s why we always respect them, providing advice and consultation to our customers even in cases where the work process can be simplified further, for the benefit of customers and suppliers involved.

certifications

You improve what you measure

Certification allows us to continue monitoring our working methods and production system, ensuring compliance with customer requirements and the creation of a product that meets our internal standards.

ISO 2015:9001

LAVORIAMO INSIEME

Do you have an idea?

Do you want to work with us?

Treviso

via Cooperativa del Lavoro, 23

31043 Fontanelle (TV)

Italy

+39 0422 809149

info@ozmeccanica.com